Fixing decking to Metadeck profiles

Metadeck watertight profiles can be fitted with all types of decking

- exotic wood (Cumaru, Ipé, Padouk...),

- local wood (treated pine, etc.),

- in wood-polymer composite

- bamboo composite (Moso, for example), - mineral resin (Millboard, for example).

You can also choose specific products such as :

- slats in Accoya or Kebony,

- Wooden slats with integrated anti-slip (Gripsure),

- porcelain stoneware slats.

To ensure that the boards hold perfectly, we recommend that you install them using stainless steel screws, screwed in from above. Avoid "clips" or "invisible fixings", which are difficult and unreliable to install on Metadeck.

The requirements of DTU 51.4 "Exterior wood decking" must be scrupulously respected, in particular:

- fastened with stainless steel through-bolts (self-drilling in this case),

- respect the spacing between the boards (often around 5 mm),

- pre-drilling and countersinking compulsory for solid wood.

- compliance with edge rules (spacing of the screw from the long edge or tip of the blade)

Mounting MetaDeck watertight profiles

You will also need to comply with standard B54-040 (exterior wood decking boards), which defines the characteristics of a decking board suited to the work to be carried out:

- minimum thickness 21 mm,

- compatibility with use class: an outdoor terrace is in use class 4,

- slenderness coefficient,

- stability in service.

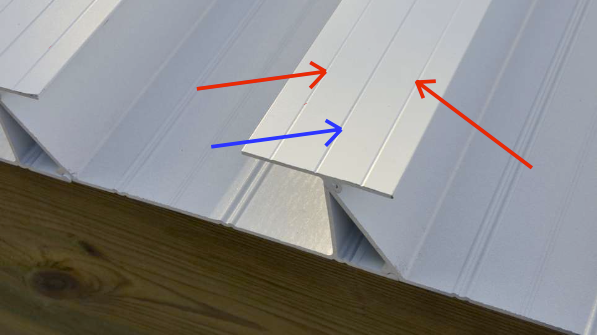

The deck boards rest on the top horizontal section of the profiles. This area is 60 mm wide, the same width as a traditional wooden joist. On the upper 60 mm screwing zone, we have created :

- 2 fine threads marking the locations of the screw lines (red arrows).

- a thick line that marks the centre, and corresponds

We recommend screwing in the boards every third profile, i.e. every 45 cm. When screwing, take care to respect this mark and not to use screws that are too long, which could pierce the sloping wall of the gutter part of the profile, creating an irreparable leak. The 60 mm screwing area is wide enough to allow two deck boards to be joined together: the ends of the boards meet at the support area and you can screw in 4 screws, neatly.

We recommend the use of :

- stainless steel 304L (A2), or stainless steel 316L (A4), in case of sea air or swimming pool nearby - self-drilling, without fins,

- countersunk head, with thread fillet,

The deck boards rest on the top horizontal part of the profiles. This area is 60 mm wide, the width of a joist.

We recommend screwing the boards every third profile, i.e. every 45 cm.

The 60 mm screwing area is wide enough to allow two deck boards to be joined together: the ends of the boards meet at the support area and you can screw in 4 screws, neatly.

When screwing in, take care to respect this mark, and not to use screws that are too long, which could pierce the sloping wall of the channel section, creating an irreparable leak.

On the upper side, we have included :

- a thick thread which marks the centre, and which therefore corresponds to the point where the two ends of the blades meet,

- 2 fine threads to mark the locations of the screw lines.

We recommend the use of :

- 304L (A2) stainless steel, or 316L (A4) stainless steel, if sea air or swimming pool nearby

- self-drilling, without fins,

- countersunk head, with thread fillet,

- torx mark,

- diameter 5 mm or 5.5 mm,

- length 45 mm.